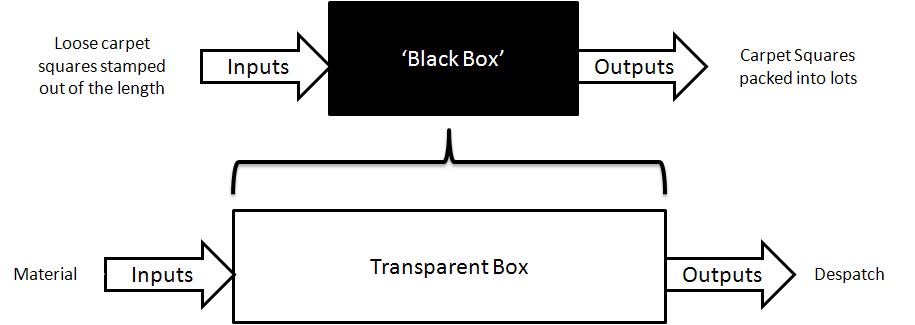

This is the starting point to concentrate on what has to be achieved (Cross 2009: 94). It allows for clearer thinking by building up a description of the problem by considering the inputs and outputs first before clouding your thoughts with how you intend to achieve it. The ‘Black Box’ does not concern itself with how something is to be done, simply what is to be done, converting inputs to outputs.

Inputs may include energy (to power devices), materials (to be worked into products) and information from/to system surroundings (Haik and Shahin 2011: 135). Figure 1 shows a simple Black Box.

Figure 1 – Basic Black Box Form.

Once all inputs and outputs have been identified, you will then allow yourself to make the Black Box into a Transparent Box and start to consider Sub-functions as in Figure 2. Sub-functions are the processes involved in turning raw material into product ie, rolling metal tube, cutting tube, forming plastic, welding, etc. This is very similar to the Flowchart you produced in the Planning and Clarification stage, that was to document the original problem, this time you’re considered the processes involved in a re-designed process.

Figure 2 – Transparent Box showing sub-functions.

Using the example of the cutting of carpet tiles and collecting them into piles to be shipped we’ll expand a Black Box into a Transparent Box. As in Figure 3.

Figure 3 – Expanding Black Box into a Transparent Box

To begin to clarify better what is required, start with outlining the sub-functions involved. As in Table 1, these have then been ordered and inserted into the Transparent Box in Figure 4. Some of these titles may sought from the work you did in to form the Flowchart in Planning and Clarification stage.

| Stamp material from entire length |

| Separate offcuts |

| Quality check |

| Count numbers for sorting |

| Combine into lots/piles |

| Pack |

| Despatch |

Table 1 – Outlining processes for Transparent Box

Figure 4 – Transparent box for packing carpet tiles.

At L1, you should concern show an appreciation of how offcuts are separated, you don’t necessarily need to specify the exact machine and it’s power requirements, but you might want to show you’ve considered that such a machine exists. At this stage you can begin delegating tasks, or narrowing your attention onto considering methods of how to complete the sub-function. This will lead onto brainstorming in the next section. Use the Flowchart you created in the Planning and Clarification stage to enter in the existing sub-functions where relevant.

Figure 5 uses an example of a washing machine and shows an advanced Transparent Box whereby not all inputs are added at the first stage. Some inputs are not required until later on in the process. There are also some outputs that leave the system before the final outcome of clean clothes.

Figure 5 – Transparent Box for a washing machine process (Cross 2009: 104)

You have still not begun concept designing yet, merely established the functions and systems that should be included.

Back to Concept Design

Back to MAE Design Model