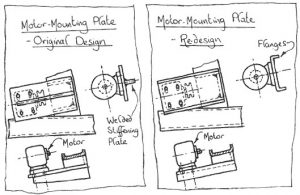

This is the last phase in which a very large number of small but essential points remain to be decided (Cross 2009: 32). Consider Figure 1, and try to see what is taking place. The design is largely complete, it’s the finer detail that is it be decided. These changes could come about as a result of trying to clarify exactly the layout in this stage. The final FE Analysis and hand calcs. may also reveal some requirement for rework.

Figure 1 – Pictoral description of detail design stage.

During this stage, commonly referred to as ‘analysis and simulation’, the designer selects the appropriate materials for each part and calculates accurately the dimensions and tolerences (Haik and Shahin 2011: 231) . While most of the selection and sizing of components occurs in the Embodiement Design stage, some components may not have been selected yet due to their own external testing (Dieter and Schmidt 2009: 388).

Use this time to list the detail that need further attention and finalise each before you move onto the next. For instance, bolt sizes, or bearing sizes, materials, hole locations etc. All need to be correct.

Back to Detail Design

Back to MAE Design Model